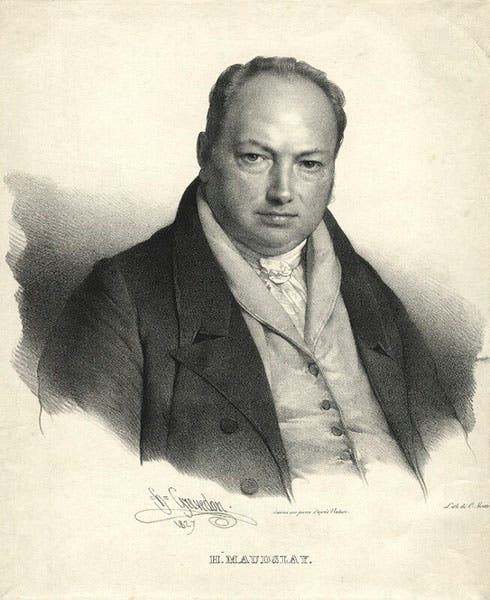

Scientist of the Day - Henry Maudslay

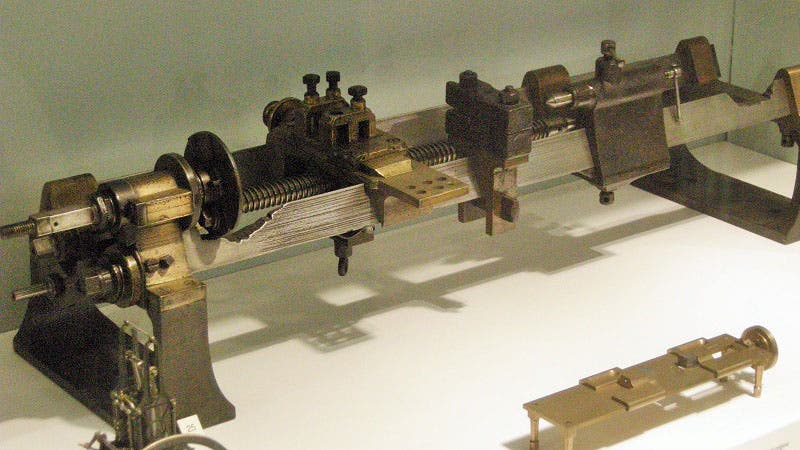

Henry Maudslay, a British machine tool maker, was born Aug. 22, 1771. Maudslay may be the most esteemed machine tool designer of the modern era, famous not only for his inventions, but for training many of the next generation of tool designers and inventors. He is best known for his screw-cutting lathe, which he had perfected by about 1797. Machinists had been cutting screws on lathes for centuries, but it was a laborious and uncertain process, with a cutting tool guided by hand and no real way to ensure a consistent pitch for the thread. Consequently, every thread was slightly different, and a nut made to fit one thread would probably not fit any other.

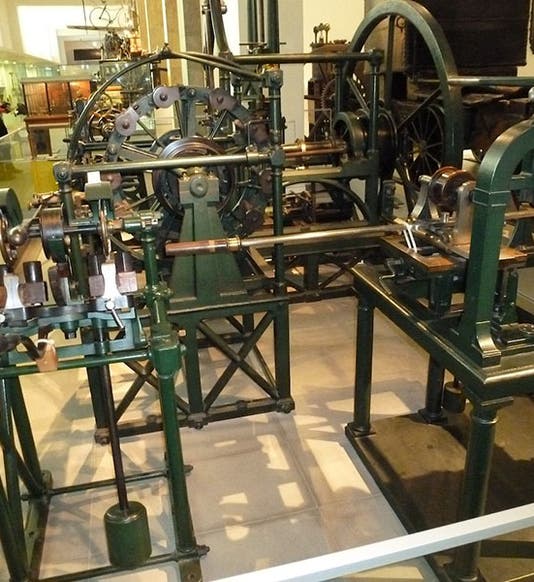

Maudslay took the separate inventions of others, added a few of his own, and incorporated them all into one unified machine. The cutting tool was not held by hand but fixed into a slide rest. The slide rest was fitted onto a long lead screw that ran parallel to the stock and was driven by the lathe, so that the tool automatically moved along as the piece turned. Finally, to produce the desired pitch (threads per inch), there was a set of replaceable gears, called change-gears, that drove the lead screw. Once the proper gears were inserted and the cutter was locked into place on the slide-rest, the operator could cut a thread on a rod, and then he could cut a hundred more just like it, and they were all truly interchangeable. There is an original Maudslay screw-cutting lathe on display at the Science Museum in London (one of the 6 that are known to survive) (third image).

Screw-cutting lathe built by Henry Maudslay, ca 1800 (Science Museum, London)

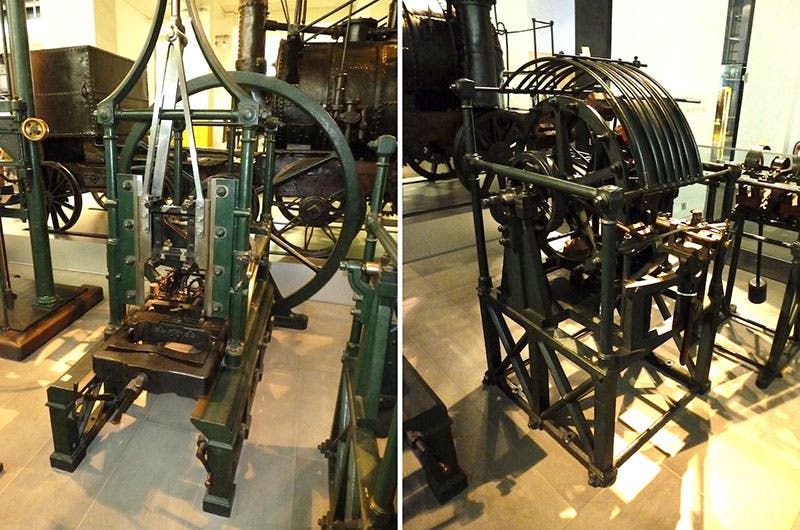

Maudslay's other major contribution to the machine revolution was to play the principal role in designing and setting up the Portsmouth Block Mills, the world’s first mass production line, a full century before Henry Ford did so in the United States. Ships of the Royal Navy used "blocks” – pulleys set in wooden shells – to raise and lower sails, and a typical warship needed almost 1000 blocks: . Before 1808, blocks were made entirely by hand, varied enormously in quality, and were very expensive to produce.

Machine for cutting mortises (left), and a shaper (right), from the Portsmouth Block Mills, built by Henry Maudslay, ca 1808, on display in the Science Museum, London (Calculating blog on Wordpress.com)

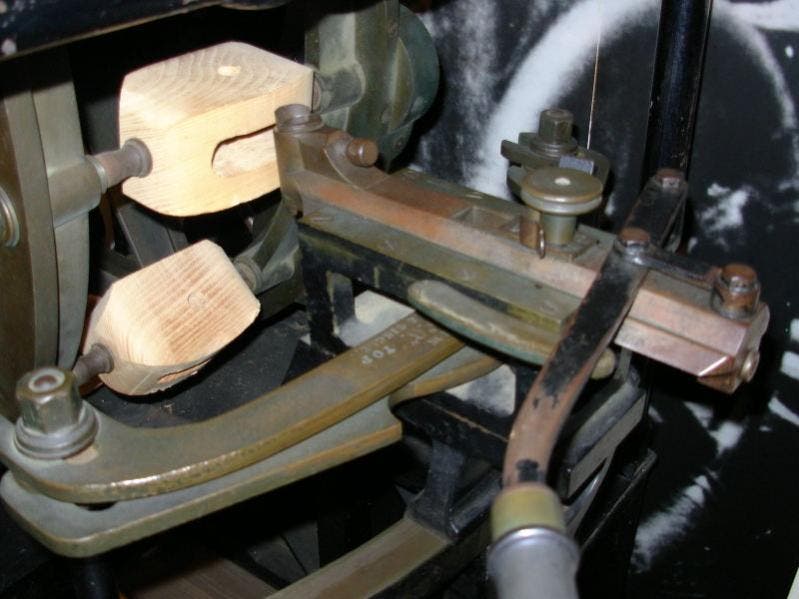

Marc Brunel, who would later install the Thames Tunnel, had the idea of automating the process, and he turned to Maudslay in 1802 to design the machinery. It took Maudslay 6 years, but he designed and built over 40 different machine tools, each one having a single specific function – cutting the shells, mortising the cutouts for the pulleys or sheaves, shaping the sheaves, drilling the holes for the sheave pins, etc. When installed at Portsmouth, the Navy had the world's first mass production factory; the machines could be run by just 10 unskilled operators, versus the hundred or so skilled workers previously required, and the factory could easily supply the 100,000 blocks, in three different sizes, needed by the Navy each year. Many of the machines survive today and are on display at the Science Museum; they are truly things of beauty, as was everything that came from Maudslay's machine tool factory (first, fourth and fifth images). A closer view of one machine shows some elm blocks in the process of being bored out (sixth image)

View of several elm blocks being bored out on one of the Portsmouth Block Mills machines (practicalmachinist.com)

We have several times in these posts referred to an engraving, printed in 1862, that purported to represent the most distinguished men of science active in Britain in 1807-08 (see here or here). This would be about the time that Maudslay was finishing the machines for Portsmouth, so it is no surprise to find that he was included. There is a copy of the engraving in the National Portrait Gallery. Of the trio at back center, just under the mirror, that is Maudslay on the left, with the round face.

Dr. William B. Ashworth, Jr., Consultant for the History of Science, Linda Hall Library and Associate Professor, Department of History, University of Missouri-Kansas City. Comments or corrections are welcome; please direct to ashworthw@umkc.edu.